Our Products

Pharmaceutical Industry

V-Cone Blender

Key Features: Unique cone design ensures complete mixing without dead zones, SS304/316 construction, easy discharge system

Applications: Uniform blending of APIs, excipients and granules in pharmaceutical production

Double Cone Blender

Key Features: Gentle tumbling action, polished interior surfaces, CIP capability

Applications: Mixing sensitive pharmaceutical powders and nutraceuticals

Tray Dryers

Key Features: Uniform heat distribution, optional HEPA filtration, corrosion-resistant construction

Applications: Drying herbal extracts, granules and pharmaceutical intermediates

Ribbon Blender

Key Features: Uniform heat distribution, optional HEPA filtration, corrosion-resistant construction

Applications: Drying herbal extracts, granules and pharmaceutical intermediates

Tablet Coating Pan

Key Features:

Perforated drum design for uniform coating

Variable speed control (2-12 RPM)

Optional auto-spray systems available

CIP/SIP compatible models

Applications:

Sugar/film coating of tablets

Enteric coating applications

Functional coating processes

Agitators

Key Features:

Custom impeller designs (anchor/paddle/turbine)

Speed range: 15-150 RPM

Bearing life >20,000 hours

ATEX-rated models available

Applications:

Liquid suspension mixing

Reactor content homogenization

Crystallization processes

Nutsch Filter

Key Features:

Combined filtration+drying

Filter area: 0.5-5 sqm

Cake thickness control

316L construction with mirror finish

Applications:

Intermediate product isolation

Solvent recovery

High-potency API handling

Candy Leaf Filter

Key Features:

Vertical leaf design

Filtration area: 2-20 sqm

Cake washing capability

Automated discharge options

Applications:

Bulk drug filtration

Clarification of syrups

Pre-filtration for sterile processes

Chocolate & Confectionery Machinery

Chocolate Ball Mill

Key Features: Particle size reduction to 18-22 microns, water-jacketed cooling, low energy consumption

Applications: Refining chocolate mass for premium quality chocolate production

Chocolate Tempering Machine

Key Features: 3-stage tempering with digital controls, crystal monitoring system

Applications: Perfect crystallization for molding and enrobing applications

Chocolate Coating Pan

Key Features: Hot/cool air system with control panel, variable speed rotation

Applications: Coating nuts, biscuits and confectionery items

Chocolate Melting Tanks

Key Features:

✔ Stainless Steel Construction (SS304/316) – Corrosion-resistant, meets food safety standards

✔ Jacketed Heating System – Uniform melting without hotspots (steam/electric options)

✔ Variable Speed Agitator – 20-60 RPM for consistent viscosity

✔ Temperature Control ±1°C accuracy with digital display

Applications:

• Tempering chocolate for molding/enrobing

• Melting cocoa butter and compounds

• Maintaining chocolate at working temperature

• Confectionery production lines

Agro/Organic Machinery

Bead Mill

Key Features: Fine grinding to 5 microns, zirconium oxide beads, VFD control

Applications: Bio-pesticide formulation and nano-fertilizer production

Coating Pan (MS Base)

Features: Heavy-duty MS, adjustable tilt

Use: Seed/pellet coating

Mixing Tank

Features: SS/MS, agitator options

Use: Liquid-solid blending

Powder Ball Mill

Features: Low contamination, high output

Use: Organic powder processing

Ribbon Blender

Features: Uniform mixing, large capacity

Use: Fertilizer production

Drum Stirrer

Features: Slow-speed, heavy-duty

Use: Compost mixing

Emamectin Extruder

Features: Adjustable die, PLC control

Use: Organic pesticide pellets

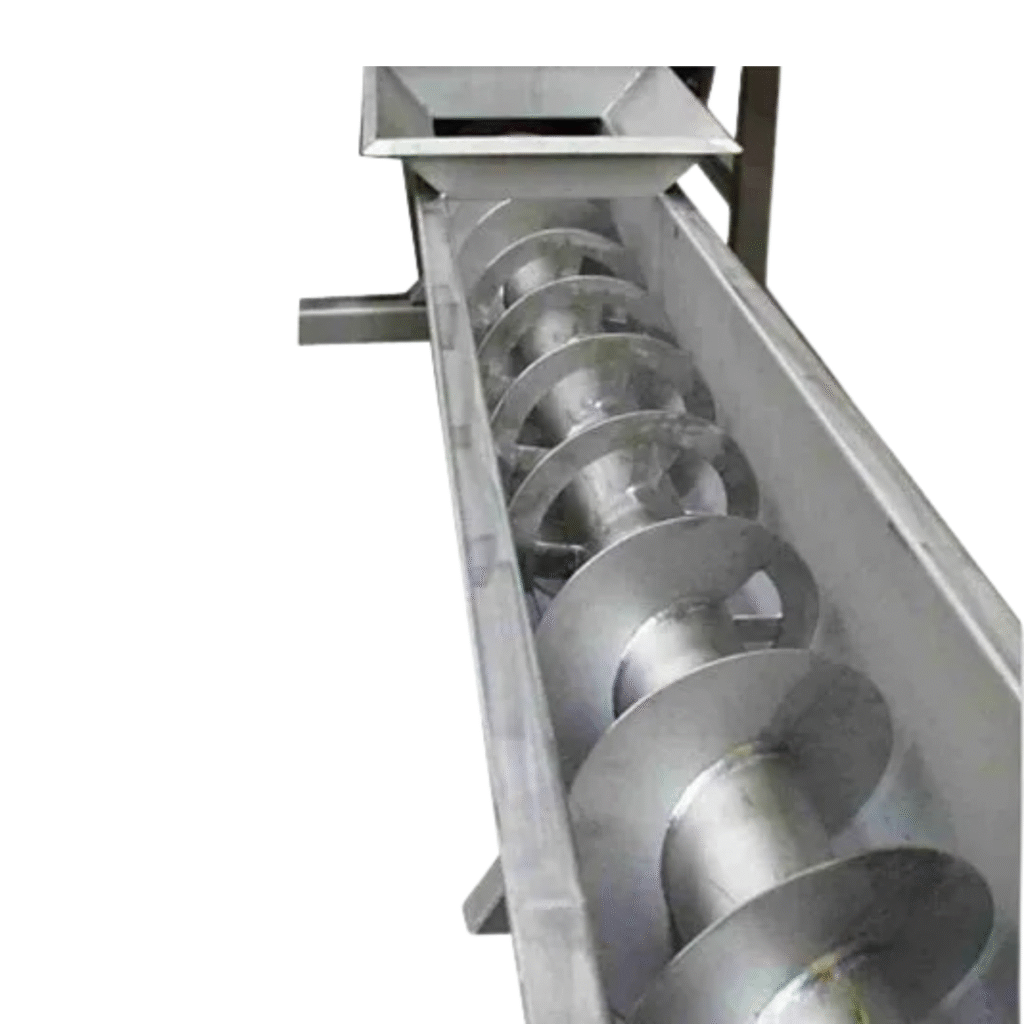

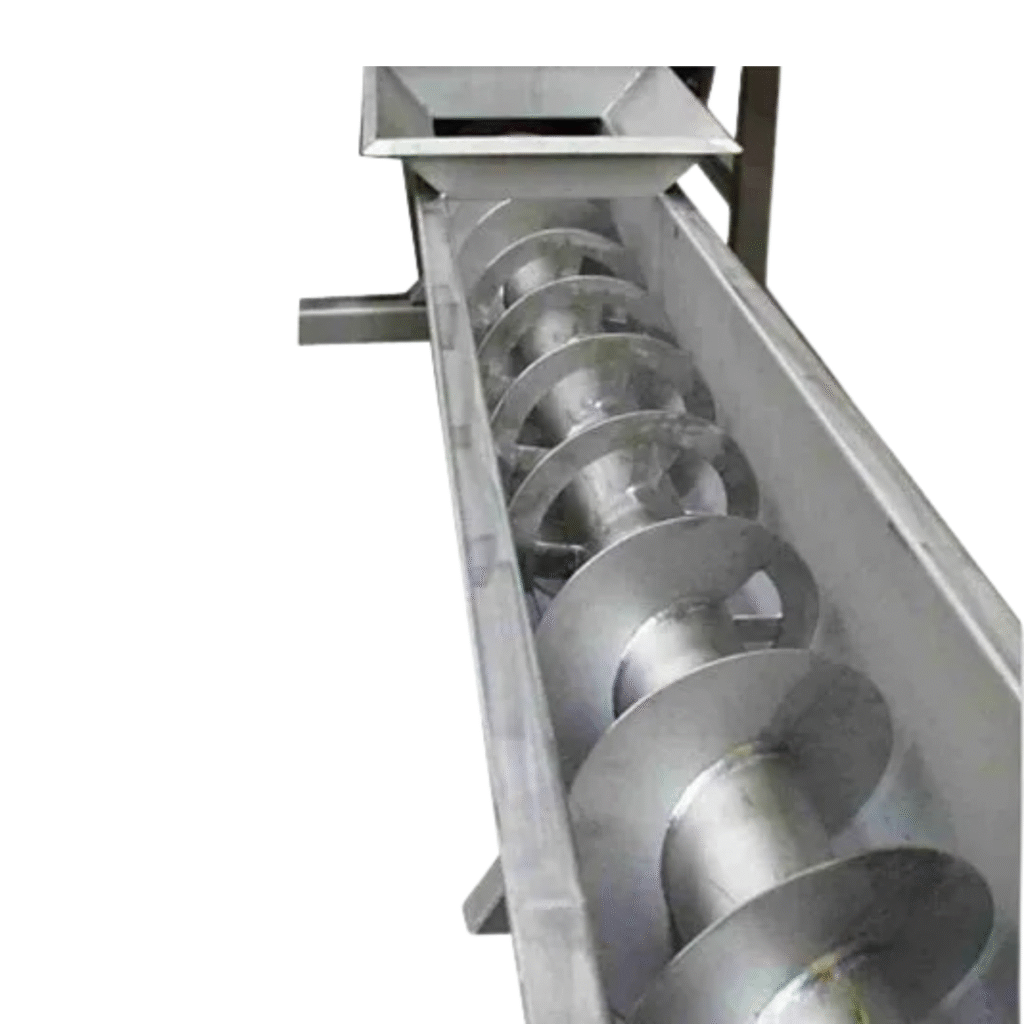

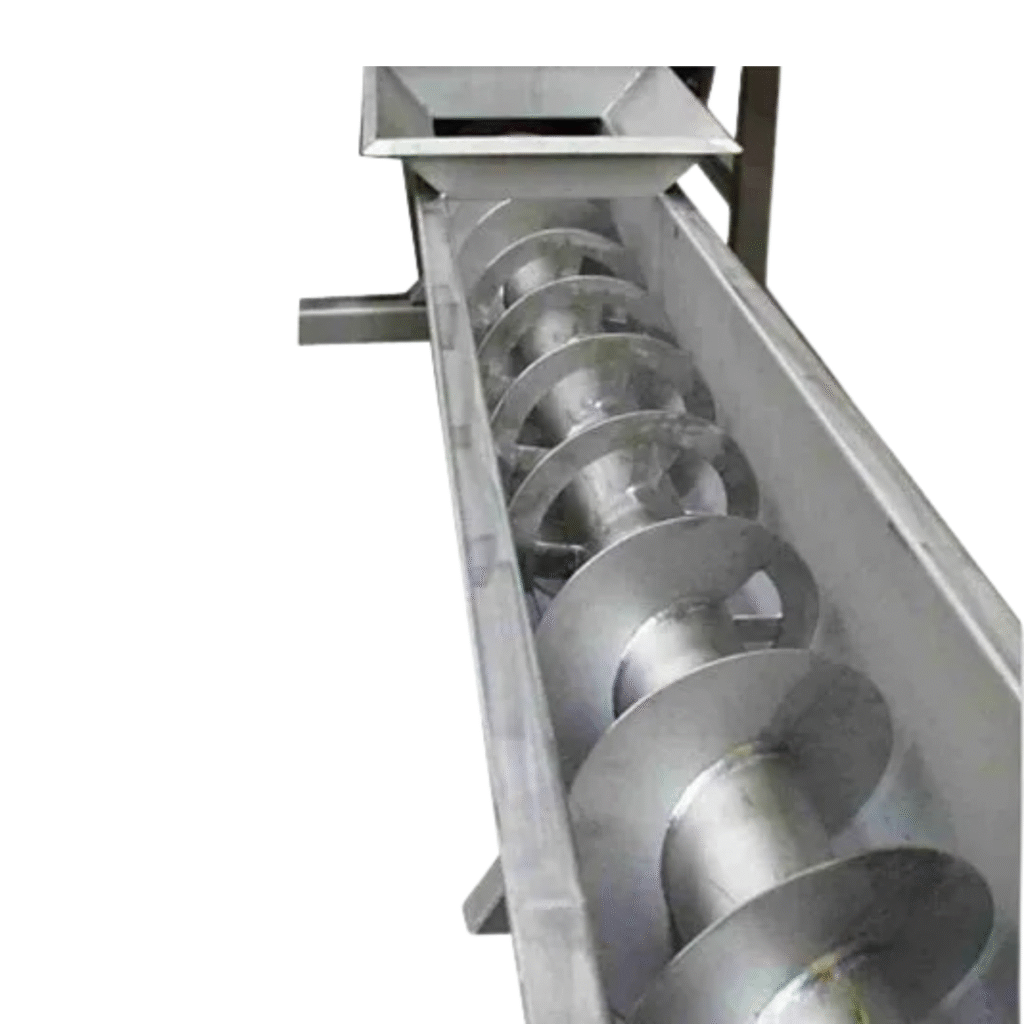

Screw Conveyor

Features: Custom lengths, abrasion-resistant

Use: Bulk material handling

Drum Stirrer

Features: Slow-speed, heavy-duty

Use: Compost mixing

Chemical Processing Equipment

Reactors and receivers

Key Features: 10 bar working pressure, multi-zone heating/cooling

Applications: Specialty chemical synthesis and pharmaceutical intermediates

Heat Exchangers

Key Features: Compact design, efficient thermal transfer

Applications: Oil & gas processing, pharmaceutical heating/cooling

Industrial Storage Tanks

Key Features: 50,000L+ capacities, modular designs

Applications: Bulk liquid storage for chemicals and edible oils